Heat pumps are becoming increasingly essential for achieving energy efficiency and sustainability goals, particularly in the context of global decarbonization efforts. The global market for heat pumps is expected to reach $120 billion by 2027, driven by rising energy prices, government incentives, and growing awareness of their environmental benefits. As the use of heat pumps expands internationally, accurate and consistent terminology is crucial for effective communication, collaboration, and accurate project estimations.

Types of heat pumps

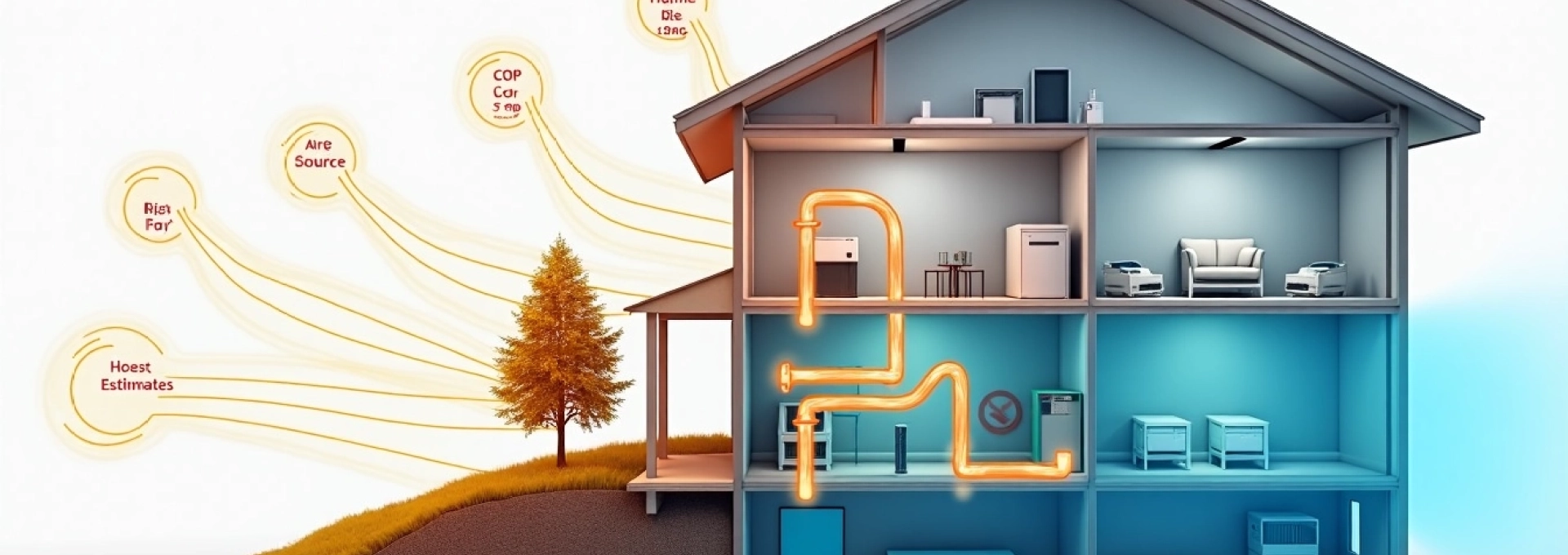

Heat pumps utilize a closed-loop thermodynamic cycle to transfer heat from one location to another. They can be categorized based on the source of heat they extract and the medium they deliver it to. Here are some common types:

Air source heat pumps (ASHP)

- Air-to-air: These systems extract heat from the surrounding air and deliver it directly into the same space, typically used for residential heating and cooling. For example, a homeowner in a temperate climate might install an air-to-air heat pump to provide heating during winter and cooling during summer.

- Air-to-water: These systems extract heat from the air and transfer it to a water-based heating system, often used for space heating and domestic hot water production. For instance, a large commercial building in a cold climate might utilize an air-to-water heat pump to provide heating and hot water for showers and other fixtures.

Ground source heat pumps (GSHP)

Ground source heat pumps extract heat from the earth, which remains relatively stable in temperature year-round. There are two main installation methods:

- Vertical: Vertical GSHPs involve drilling wells and installing pipes to transfer heat from the earth to the heat pump system. This method is suitable for areas with limited ground space. For example, a vertical GSHP could be installed in a densely populated urban area where horizontal installation is not feasible.

- Horizontal: Horizontal GSHPs require larger areas of ground space and involve burying pipes within trenches for heat transfer. This method is typically preferred for larger properties with available land. For instance, a suburban home with a spacious yard might benefit from a horizontal GSHP installation.

Water source heat pumps (WSHP)

Water source heat pumps utilize water bodies like lakes, rivers, or groundwater as a source of heat. They can be categorized as follows:

- Open loop: Open loop WSHPs directly use water from a surface water body for heat transfer. This method might be less efficient in colder climates due to the potential for water freezing. For example, an open loop WSHP could be installed near a lake to provide heating for a resort complex.

- Closed loop: Closed loop WSHP systems circulate a non-freezing fluid in a closed loop through a heat exchanger to transfer heat from the water source to the heat pump. This method is more energy-efficient and less susceptible to freezing issues. For example, a closed loop WSHP could utilize groundwater to provide heating and hot water for a large residential development.

Other types

While less common, other heat pump types include geothermal heat pumps which tap into the earth's heat through deeper wells, and absorption heat pumps that utilize a different process using a working fluid and a heat source like solar energy.

Key components and technical terms

The operation of a heat pump relies on a closed-loop thermodynamic cycle that involves the following components:

Compressor

The compressor is a key component that compresses the refrigerant, increasing its temperature and pressure. The compressed refrigerant is then passed to the condenser. In essence, the compressor acts like a heart of the heat pump, driving the refrigerant cycle.

Condenser

The condenser releases the heat absorbed by the refrigerant into the desired space or medium. There are two common types of condensers:

- Air-cooled: Air-cooled condensers release heat into the surrounding air through fans and fins. This type is most common in residential and commercial settings. For example, an air-cooled condenser in a home might exhaust heat outdoors through a fan.

- Water-cooled: Water-cooled condensers use water to absorb heat from the refrigerant, then release the heat elsewhere. This type is often found in larger commercial systems or settings where air-cooled condensers are not feasible. For instance, a large water-cooled condenser might be used in a factory to release excess heat into a cooling tower.

Evaporator

The evaporator absorbs heat from the source, be it air, water, or the earth, and transfers it to the refrigerant. As the refrigerant absorbs heat, it changes from a liquid to a gas. The evaporator acts as the "heat sink" of the system, extracting heat from the environment.

Expansion valve

The expansion valve controls the flow of refrigerant between the condenser and evaporator, maintaining the correct pressure and temperature conditions for efficient operation. By adjusting the refrigerant flow, the expansion valve ensures optimal heat transfer and system performance.

Refrigerant

Refrigerant is the working fluid that cycles through the heat pump, absorbing and releasing heat during the process. Common refrigerants used internationally include R410A and R32, each with different environmental impact and efficiency characteristics. The choice of refrigerant is crucial, as it can impact the overall energy efficiency and environmental footprint of the heat pump system.

COP (coefficient of performance)

The Coefficient of Performance (COP) is a measure of a heat pump's efficiency. It represents the ratio of heat output to energy input. A higher COP indicates greater efficiency. For example, a heat pump with a COP of 4 will produce 4 units of heat for every 1 unit of electricity consumed. COP values are influenced by factors such as the ambient temperature, the temperature difference between the source and the space being heated or cooled, and the type of heat pump. The COP is a crucial factor in determining the overall energy savings and operational cost of a heat pump system.

SEER (seasonal energy efficiency ratio)

SEER (Seasonal Energy Efficiency Ratio) is a measure of a heat pump's energy efficiency over an entire cooling season. It is calculated by dividing the total cooling output by the total energy input over a specific period, typically a year. SEER is an important metric for comparing the energy efficiency of different heat pumps and assessing their potential impact on energy consumption and costs.

Control systems

Control systems play a vital role in optimizing heat pump operation. Thermostats, inverters, and smart controls are essential components that regulate system settings, adjust operating cycles, and optimize performance based on various factors like ambient temperature, energy demand, and user preferences. For instance, a smart thermostat can learn user preferences and optimize the heat pump's operation based on real-time data and weather conditions, leading to improved energy efficiency and comfort.

Estimation and project development

Successful international heat pump projects rely on accurate estimations and efficient project development. This involves considering various factors, including international standards, site assessment, cost estimation, and financing options.

International standards

International standards and codes ensure consistency and safety in heat pump design, installation, and operation. Adhering to these standards is crucial for seamless project execution and ensuring compatibility across different countries. Key standards include ISO 13857 for heat pumps and ASHRAE Standard 15 for refrigeration.

Site assessment

Thorough site assessment is essential for determining the feasibility and optimal design of a heat pump system. Key considerations include climate conditions, soil characteristics, existing infrastructure, and potential energy sources. For example, a project in a hot and humid climate might require a larger capacity heat pump than one in a temperate region.

Cost estimation

Accurate cost estimation is vital for budgeting and project planning. Key cost factors include material costs, labor rates, installation expenses, and potential incentives. Cost estimation can vary significantly across different countries due to factors like material availability, labor costs, and local regulations. In some countries, government subsidies and tax incentives might be available to encourage heat pump adoption. For example, in Germany, the "Renewable Energy Sources Act (EEG)" provides financial support for renewable energy systems, including heat pumps.

Financing

Financing plays a critical role in making heat pump projects accessible. Government incentives, subsidies, and loan programs can help offset upfront costs and encourage adoption. Additionally, private sector investments and partnerships are becoming increasingly important in funding large-scale heat pump projects. For example, in some countries, government subsidies might cover a portion of the cost of a new heat pump installation for residential homes.

Environmental considerations

Heat pumps offer significant environmental benefits by reducing energy consumption and carbon emissions. However, it's essential to consider potential environmental impacts and mitigate risks.

Energy efficiency

Heat pumps are highly energy-efficient, reducing reliance on fossil fuels and greenhouse gas emissions. In many countries, heat pumps are being promoted as a key technology for decarbonizing heating and cooling sectors. For instance, in some European countries, heat pumps are being incentivized through policies aimed at reducing carbon emissions and improving energy efficiency. The European Union's "Energy Performance of Buildings Directive (EPBD)" sets energy performance standards for buildings, including requirements for heating and cooling systems, which encourage the adoption of heat pumps.

Refrigerant leakage

Refrigerant leakage can contribute to greenhouse gas emissions. International regulations are being implemented to phase out high-GWP refrigerants and promote alternatives with lower environmental impact. For example, the European Union's F-Gas regulation limits the use of high-GWP refrigerants and promotes the adoption of alternatives like R32, which has a lower Global Warming Potential (GWP).

Sustainable practices

Sustainable practices are crucial for minimizing the environmental impact of heat pump projects throughout their lifecycle. Responsible sourcing of materials, energy-efficient manufacturing processes, and proper disposal at the end of life are essential for environmental stewardship. For example, manufacturers are increasingly using recycled materials in their products, and companies are developing systems for recycling and reusing heat pump components at the end of their useful life.

Future trends

Technological advancements and international cooperation are driving the continued evolution of heat pump technologies.

Technological advancements

Heat pump technology is constantly evolving, with advancements in efficiency, integration with renewable energy sources, and smart control systems. Innovations in materials, design, and manufacturing are leading to more compact, quieter, and energy-efficient systems. For instance, new heat pump models are being developed that can integrate with solar panels or other renewable energy sources, further reducing reliance on fossil fuels. These advancements are making heat pumps even more attractive for homeowners and businesses seeking to reduce their carbon footprint and save on energy costs.

International cooperation

International collaboration is critical for accelerating the adoption of heat pump technologies and achieving global sustainability goals. Governments, research institutions, and industry stakeholders are working together to develop standards, promote best practices, and foster innovation. For example, international organizations are supporting research and development efforts to improve heat pump efficiency and promote their widespread use across different regions.

Understanding technical terminology is essential for navigating the complexities of international heat pump projects. By embracing consistent terminology, fostering communication, and promoting collaboration, we can unlock the full potential of heat pumps for a more sustainable future.